The Biggest Pain Points for Factory Facility Management

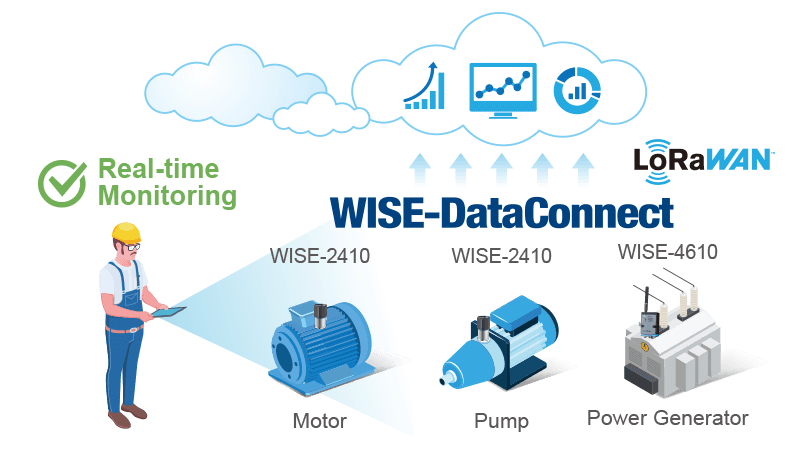

Difficult Assets & Equipment Management

Our Solutions

- Reduce equipment downtime

- Improve OEE statistics

- Enhance local alarm system

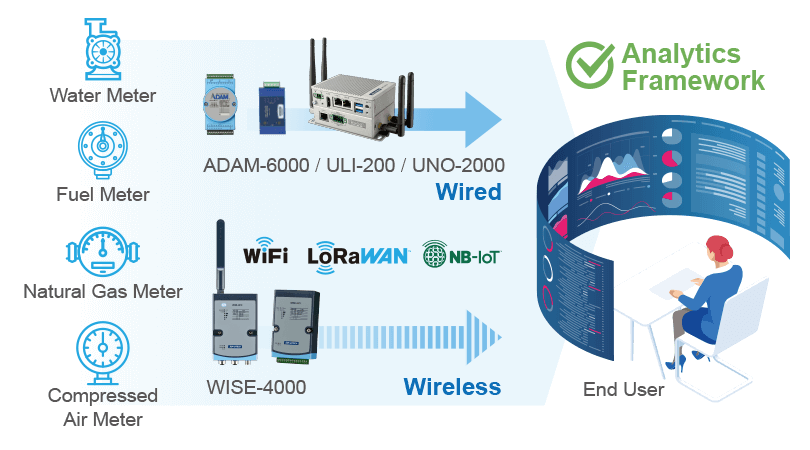

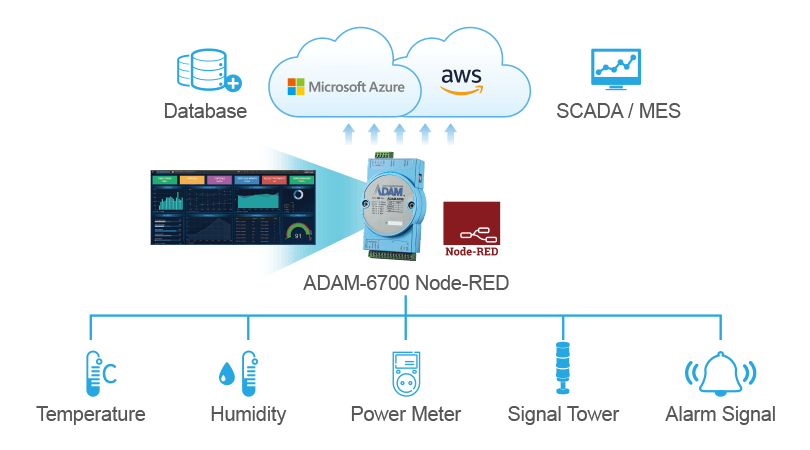

Inefficient Utility Management

Our Solutions

- Reduce water / gas / power consumption by real-time monitoring

- Enhance alarm and notification system

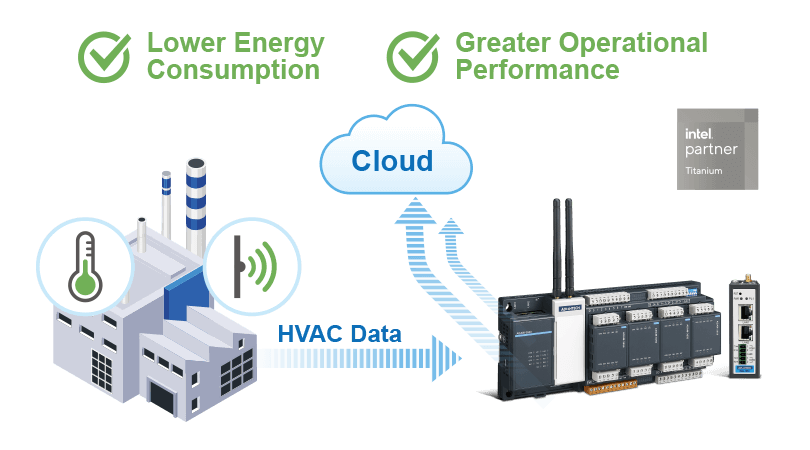

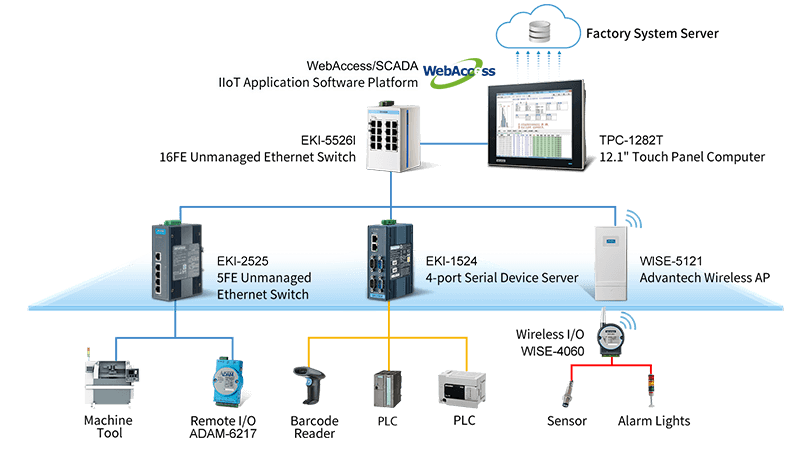

Ineffective Process Control

Our Solutions

- Reduce costs by optimizing production process

- Provide comprehensive monitoring

- Plan corrective maintenance

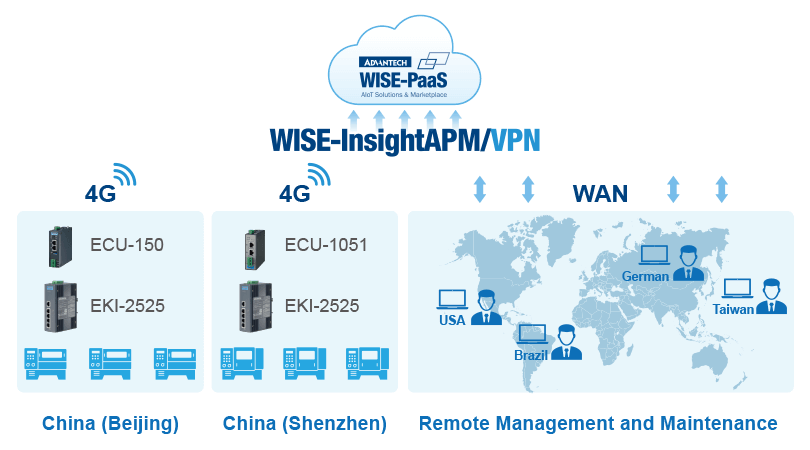

Restricted to On-site Inspection

Our Solutions

- Reduce on-site visits by monitoring remotely

- Save working time by using dashboard for data visualization

- Set up a utility benchmarking plan