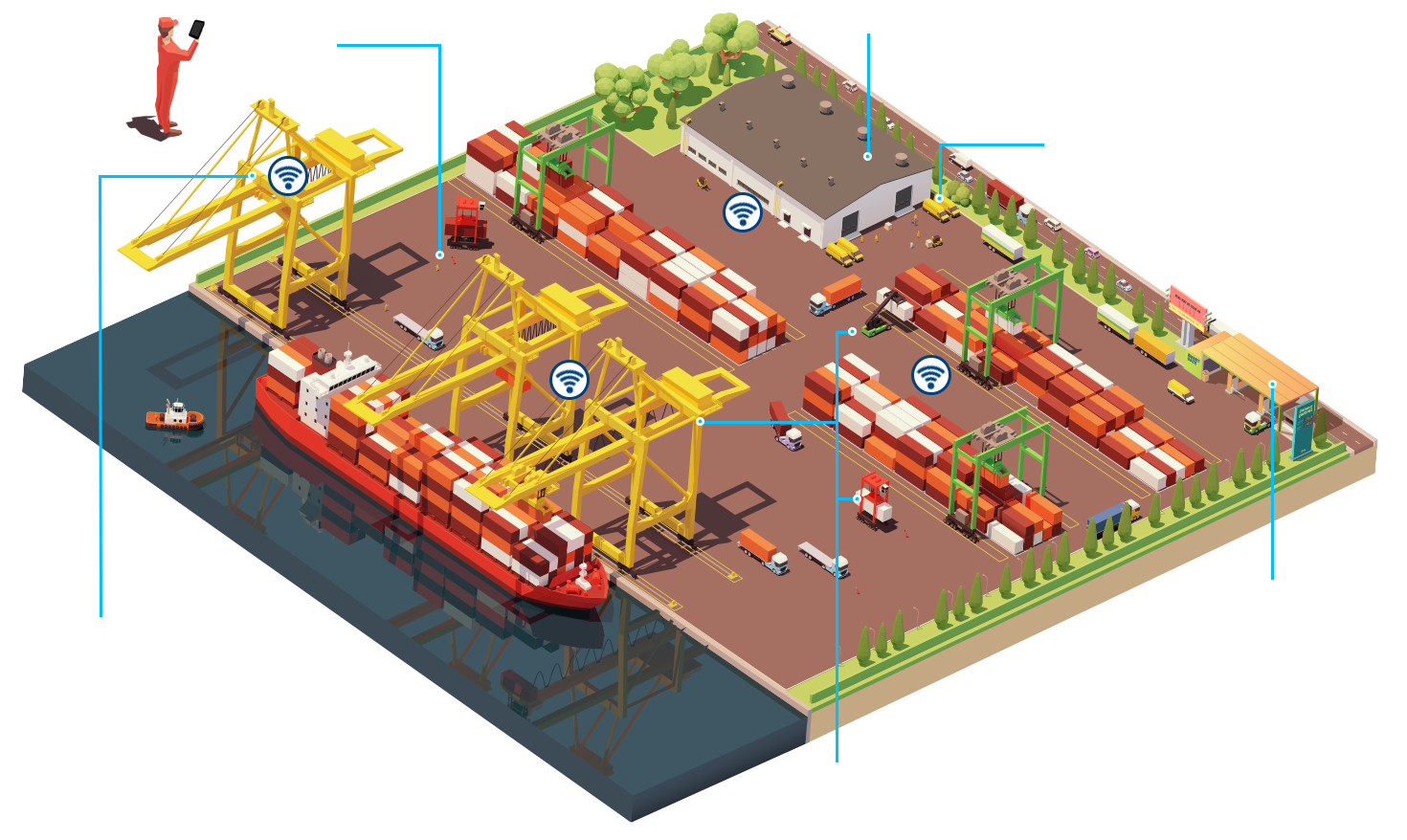

Due to increasing size and volume of cargo ships, global container ports continue to face new challenges with daily yard operations, goods handling, and equipment management. To tackle these issues, ports are progressively adopting innovations and automated solutions to enhance operational efficiency, safety, and security. The integration of new-generation technologies such as the Internet of Things (IoT), 5G, big data, AI, etc., has emerged as a key driver for the digital transformation of modern ports. As a leading provider of IoT solutions, Advantech draws on its extensive experience in industrial automation, intelligent logistics, and smart city solutions to offer a comprehensive port management solution. This solution facilitates the development of smarter applications and fosters innovations for the advancement of Smart Port 4.0.

Feature Highlights

Saltwater Corrosion Resistance

with Industrial-Grade Designs

Edge computing and wireless communication devices deployed in outdoor environments at container ports face a wide range of environmental conditions, including high and low temperatures, humidity, dust, and saltwater exposure. To meet these demanding requirements, Advantech has developed industrial-grade devices specifically designed for such environments. These rugged devices offer a durable system with water and dust protection, shock and vibration tolerance, and a wide operating temperature range.

Increased Efficiency and Visibility

with Intelligent Connected Devices

Within a smart port, all assets such as stackers, cranes, and trucks, are equipped with edge computing devices and connected to the network to enable real-time data processing and analysis. This integration enhances the efficiency and precision of cargo handling, asset tracking, and task management. Connecting IoT devices, including tablets, sensors, and cameras, plays a crucial role in collecting yard environment data, monitoring container movements, optimizing traffic flow, and enhancing supply chain visibility.

Uninterrupted Data Transmission

with Reliable Wireless Connectivity

In order to implement IoT solutions across a large fleet of connected assets, high-speed and reliable wireless technologies that enable real-time network services in open areas are essential for smart ports. Advantech provides a comprehensive range of Wi-Fi, LoRaWAN, and NB-IoT solutions that provide versatile and dependable options for connecting edge devices to cloud-based TOS and WMS management systems.

Applications

Yard Field Service

- • Enabling efficient cargo inspections and issuing of reports.

- • Streamlining of port workflows and workforce management.

- • Support for real-time asset tracking and operation recording.

AIM-78S / AIM-68

PWS-872

Port Warehouse Management

- • Support for various warehouse applications, such as order picking, inventory management, and cold storage.

- • Providing seamless processing of goods and storage for port customers.

DLT-V73

AIM-75S / AIM-78S

Cold Chain Management

- • Display of real-time temp. data of all sensors installed in the location.

- • Enabling in-depth monitoring and management of the end-to-end cold chain.

- • Providing managers with a quick overview of the KPI of different locations.

TREK-120

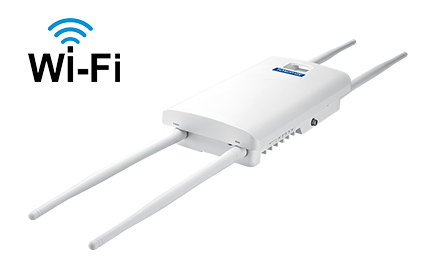

Wireless Communication

- • A variety of wireless solutions for vertical domain applications in the smart port area.

- • LoRaWAN technology allows sensors and IoT devices to be deployed in inaccessible or remote parts of the port, enhancing asset tracking and monitoring with its long-range capabilities and low power consumption.

- • High-speed and real-time dual-band Wi-Fi and LTE enable real-time asset tracking and optimization of port operations.

EKI-6333AC-2G

WISE-6610

Intelligent Connected Cranes and Stackers

- • Display of work orders from the management system and movement of containers in an optimized sequence.

- • Collection of container information which is shared with the management system for task monitoring and further data analysis.

DLT-V72 Facelift

TREK-773

Smart Gate & Truck Management

- • Camera system that can automatically identify vehicle plate, chassis number, and container number.

- • In-vehicle computers on trucks transfer all the necessary data in real-time to the gate computer, including plate number, driver's license, and container number.

- • Gate computers verify the identity of trucks, grant access, and send tasks to truck drivers.

TREK-60

TREK-773

UBX310F

Yard Field Service

- • Enabling efficient cargo inspections and issuing of reports.

- • Streamlining of port workflows and workforce management.

- • Support for real-time asset tracking and operation recording.

AIM-78S / AIM-68

PWS-872

Port Warehouse Management

- • Support for various warehouse applications, such as order picking, inventory management, and cold storage.

- • Providing seamless processing of goods and storage for port customers.

DLT-V72 Facelift

AIM-75S / AIM-78S

Cold Chain Management

- • Display of real-time temp. data of all sensors installed in the location.

- • Enabling in-depth monitoring and management of the end-to-end cold chain.

- • Providing managers with a quick overview of the KPI of different locations.

TREK-120

Wireless Communication

- • A variety of wireless solutions for vertical domain applications in the smart port area.

- • LoRaWAN technology allows sensors and IoT devices to be deployed in inaccessible or remote parts of the port, enhancing asset tracking and monitoring with its long-range capabilities and low power consumption.

- • High-speed and real-time dual-band Wi-Fi and LTE enable real-time asset tracking and optimization of port operations.

EKI-6333AC

EKI-7700

Intelligent Connected Cranes and Stackers

- • Display of work orders from the management system and movement of containers in an optimized sequence.

- • Collection of container information which is shared with the management system for task monitoring and further data analysis.

DLT-V72 Facelift

TREK-773

Smart Gate & Truck Management

- • Camera system that can automatically identify vehicle plate, chassis number, and container number.

- • In-vehicle computers on trucks transfer all the necessary data in real-time to the gate computer, including plate number, driver's license, and container number.

- • Gate computers verify the identity of trucks, grant access, and send tasks to truck drivers.

TREK-60

TREK-773

UBX-310F

Resources

Product Offerings

DLT-V73

10.4/12.1" Rugged VMT with 3 or 10 function keys

DLT-V83

10.4/12.1/15.1" Rugged VMT available with 5/9/26 function keys

DLT-V72 Facelift

10.4/12.1" Rugged VMT with 12 function keys

DLT-V7210 K/KD

10.1" Rugged VMT with full keyboard and screen defroster

DLT-V7212/V7215 P+

12.1/15" Rugged VMT with PCAP touchscreen

DLT-V6210 Facelift

10.4" Rugged VMT with sunlight-readable display

- Smart VMTs for container cranes and stackers

- Superior Wi-Fi roaming capabilities

- IP66/65-rated water and dust protection

- Glove-compatible touchscreen and optional screen defroster

- Front panel with IK08 rating for impact resistance

- MIL-STD-810F and 5M3 tested for shock/vibration tolerance

- Wide operating temperature range (-30 ~ 50 °C / -22 ~ 122 °F)

-

Certified with Navis N4 system

- Features vary by models

AIM-65

8" Industrial-grade tablet with Windows OS

AIM-68

10.1" Industrial-grade tablet with Windows OS

AIM-75S

8” Industrial-grade tablet with GMS and Android 12 OS

AIM-78S

10.1” Industrial-grade tablet with Android 10 OS

PWS-872

10.1” Rugged tablet with Windows OS

- 8" & 10" industrial rugged tablets for mobile field operations

- Support Windows and Android OS

- Glove-compatible touch and sunlight-readable screen

- Rugged design with drop protection

- IP65-rated water and dust protection

- Seamless Wi-Fi, LTE, and GPS wireless connectivity

- Versatile extension, docking, mounting, and peripherals

- Swappable battery for long-duration operation

TREK-60

Modular AI platform

TREK-570

Rugged Computing Box for Fleet Management

TREK-303R FL

7" in-vehicle smart display with smart display port 2.0

TREK-773

7" All-in-One Ultra Rugged Mobile Data Terminal

TREK-306P FL

10" in-vehicle smart display with smart display port 2.0

- Compact in-vehicle computing boxes for in-vehicle control system

- Modular design supports the latest RF communication technologies

- Advanced video surveillance system with AI accelerator for video AI capabilities

- MIL-STD-810F and 5M3 certified for shock/vibration tolerance

- Wide operating temperature range (-30 ~ 70 °C / -22 ~ 158 °F)

- Rugged in-vehicle display can be easily paired with a TREK computing box via a single-cable connection

TREK-120

LoRa-Based Cold Chain Temperature & Humidity Sensor

USM-S62

LoRa Data Gateway

USM-S66

LoRa Vehicle Gateway

- LoRa technology for efficient long-range wireless data transmission

- Sensors can be configured to trigger alerts for real-time management

- Easy and simple installation in a diverse range of refrigerated vehicles

- IP65-rated protection from water and dust ingress

- Supports IoT cloud services for centralized, real-time exception management

- Long battery life (up to 36 months, depending on usage scenario)

EKI-6333AC-2G

Dual-Band Wi-Fi AP/Client

EKI-1652WT

EN50155 Industrial M12 Wi-Fi/LTE Router

WISE-6610

LoRaWAN Gateway

EKI-6333AC-2G

- WLAN transmission rate of up to 1167 Mbps

- IP65 waterproof certification

EKI-1652WT

- Anti-vibration M12 design

- Wide range power input: 24/48/72/96/110 VDC

WISE-6610

- Long-range wide-area IoT gateway

- LoRaWAN protocol for closed and public system applications