Cost

The cost of the BESS is always the primary concern, and when implementing an IoT-based BESS, users should take into account the costs of hardware, software, installation, and maintenance.

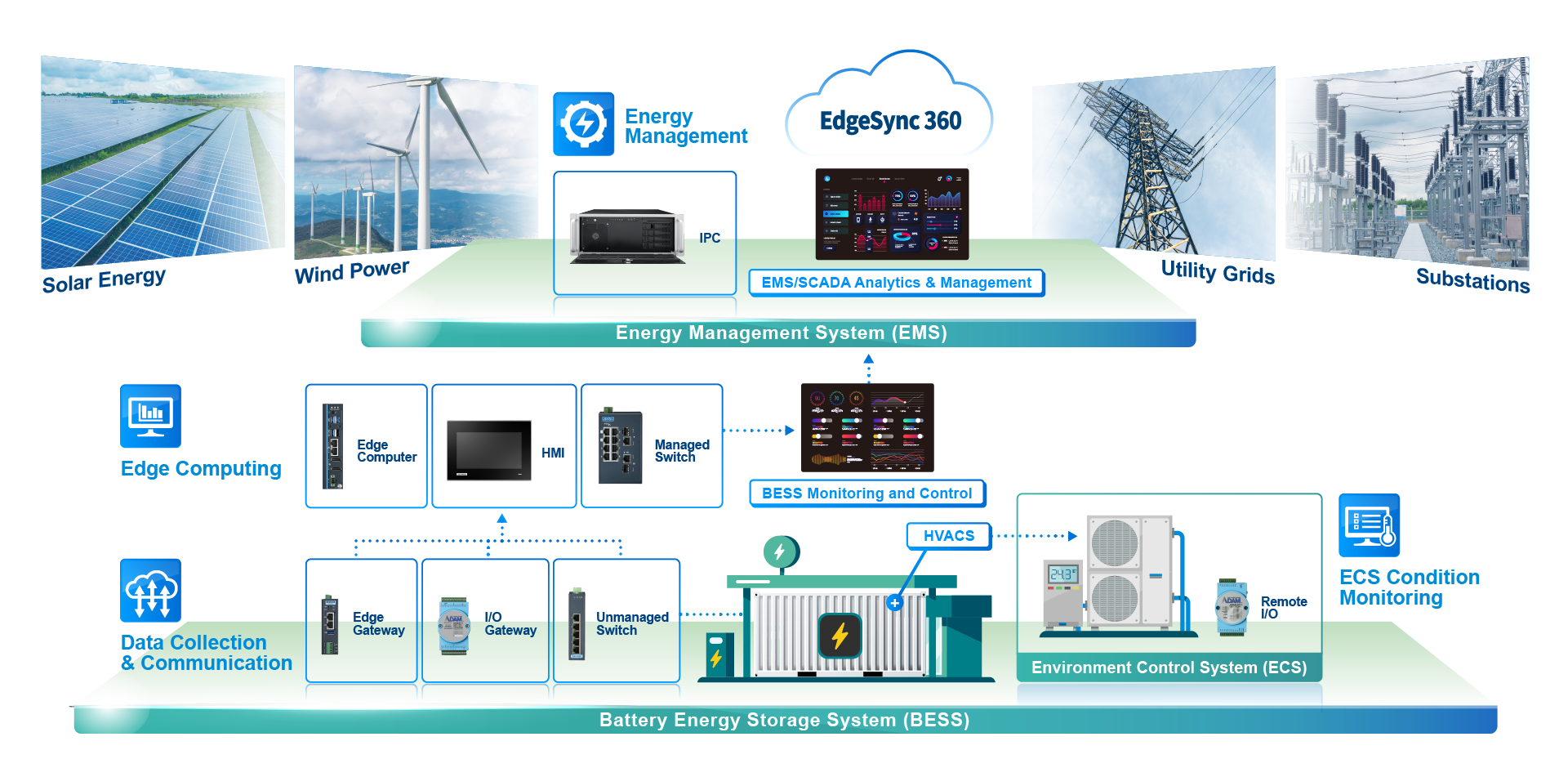

As the global demand for energy increases, so does the need for innovative energy storage solutions. Battery Energy Storage System (BESS) has been an integral part of energy generation, transmission, distribution, and consumption. With the growth of renewable energy and the need for de-carbonization, BESS has become more important than ever.

To minimize emissions, BESS can leverage renewable energy resources more effectively so we can rely on less grid power.

The management of distributed energy such as solar and wind power drives the need for micro grids and BESS.

With IoT technology as the enabler, BESS plays a key role in optimizing and balancing real-time power demand and supply.

When it comes to integrating IoT in BESS for grid digitalization and decentralization, there are several challenges that need to be tackled.

The cost of the BESS is always the primary concern, and when implementing an IoT-based BESS, users should take into account the costs of hardware, software, installation, and maintenance.

A scalable BESS is essential for future growth and development. With Advantech’s complete IoT product portfolios, users can build IoT infrastructure for their BESS with great scalability.

A well-connected BESS needs to utilize reliable and secure communication infrastructure, as well as robust computing power that can work autonomously. Advantech's IoT sensing, computing and communication products enable users to create a well-connected system for their BESS without worrying about system integration.

To maintain the stable operation of BESS, Advantech’s remote I/O gateways and edge computers can effectively monitor BMS, EMS, and ECS conditions to ensure the safety of BESS, while the industrial switches, routers and protocol gateways provide robust network infrastructure with VPN and IT protocols for enhanced data security.

Whether BESS is operating at a large or small scale, it requires effective remote device management to ensure overall grid stability and firm power capacity. The Advantech IoT device management service, EdgeSync 360, can connect and manage all IoT devices whether on a public cloud or on premises. EdgeSync 360 can also easily integrate with 3rd party platforms via open API for seamless remote data and device management.

The cost of the BESS is always the primary concern, and when implementing an IoT-based BESS, users should take into account the costs of hardware, software, installation, and maintenance.

A scalable BESS is essential for future growth and development. With Advantech’s complete IoT product portfolios, users can build IoT infrastructure for their BESS with great scalability.

A well-connected BESS needs to utilize reliable and secure communication infrastructure, as well as robust computing power that can work autonomously. Advantech's IoT sensing, computing and communication products enable users to create a well-connected system for their BESS without worrying about system integration.

To maintain the stable operation of BESS, Advantech’s remote I/O gateways and edge computers can effectively monitor BMS, EMS, and ECS conditions to ensure the safety of BESS, while the industrial switches, routers and protocol gateways provide robust network infrastructure with VPN and IT protocols for enhanced data security.

Whether BESS is operating at a large or small scale, it requires effective remote device management to ensure overall grid stability and firm power capacity. The Advantech IoT device management service, Edge365, can connect and manage all IoT devices whether on a public cloud or on premises. Edge365 can also easily integrate with 3rd party platforms via open API for seamless remote data and device management.

BESS applications are commonly divided into “front-of-the-meter” and “behind-the-meter” applications; both can be paired with different BESS at different capacities.

Front-of-the-meter BESS refers to energy storage at the energy generation and transmission sites, i.e., renewable energy and utility grids, which require large-size grid-scale BESS. On the other hand, behind-the-meter BESS has the energy storage at the sites of energy consumption, i.e., industrial and commercial locations or homes with smaller BESS.

This is where Advantech IoT technologies come in. For BESS at a large or small scale, you can always find the right IoT solution for your BESS application. By leveraging our extensive range of sensing, communication, and computing products, we are helping to build sustainable BESS that are reliable and flexible.

BESS applications are commonly divided into “front-of-the-meter” and “behind-the-meter” applications; both can be paired with different BESS at different capacities.

Front-of-the-meter BESS refers to energy storage at the energy generation and transmission sites, i.e., renewable energy and utility grids, which require large-size grid-scale BESS. On the other hand, behind-the-meter BESS has the energy storage at the sites of energy consumption, i.e., industrial and commercial locations or homes with smaller BESS.

This is where Advantech IoT technologies come in. For BESS at a large or small scale, you can always find the right IoT solution for your BESS application. By leveraging our extensive range of sensing, communication, and computing products, we are helping to build sustainable BESS that are reliable and flexible.

SCADA is the information center in an EMS. SCADA can be run on 2 sets of industrial computers as to have redundancy.

There are several sub-systems in BESS, such as PCS, BMS, and ECS. The network infrastructure, including Ethernet switches and media converters, is the key to connecting all the systems together.

The protocol gateway can enhance the communication performance for common protocols such as Modbus/RTU, Modbus/TCP, CANBus, IEC 61850, and DNP3.

To ensure the stability of BESS, it is essential to monitor the environment. In ECS, the critical equipment is UPS and HVAC. Remote I/O modules can provide monitoring 24/7.

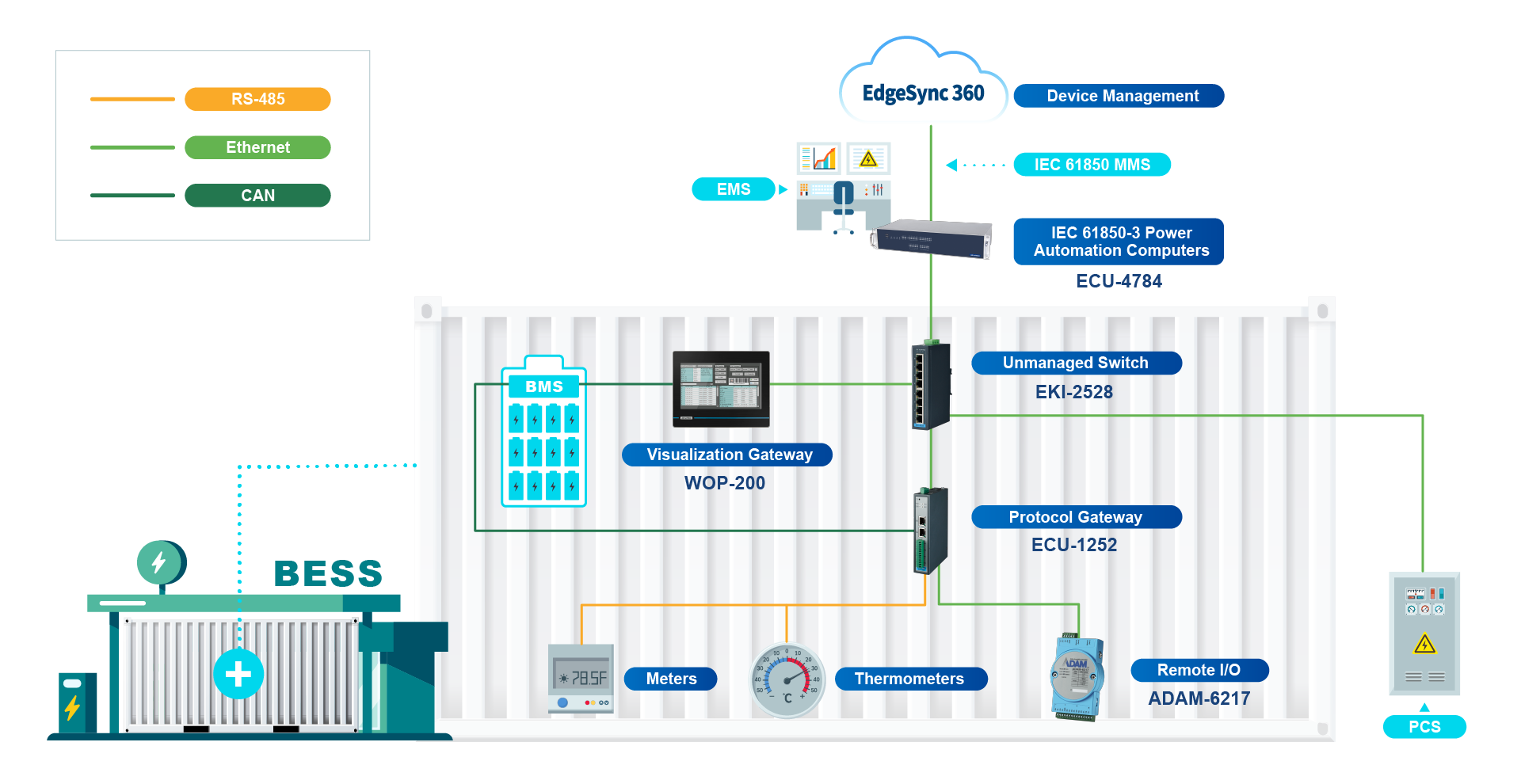

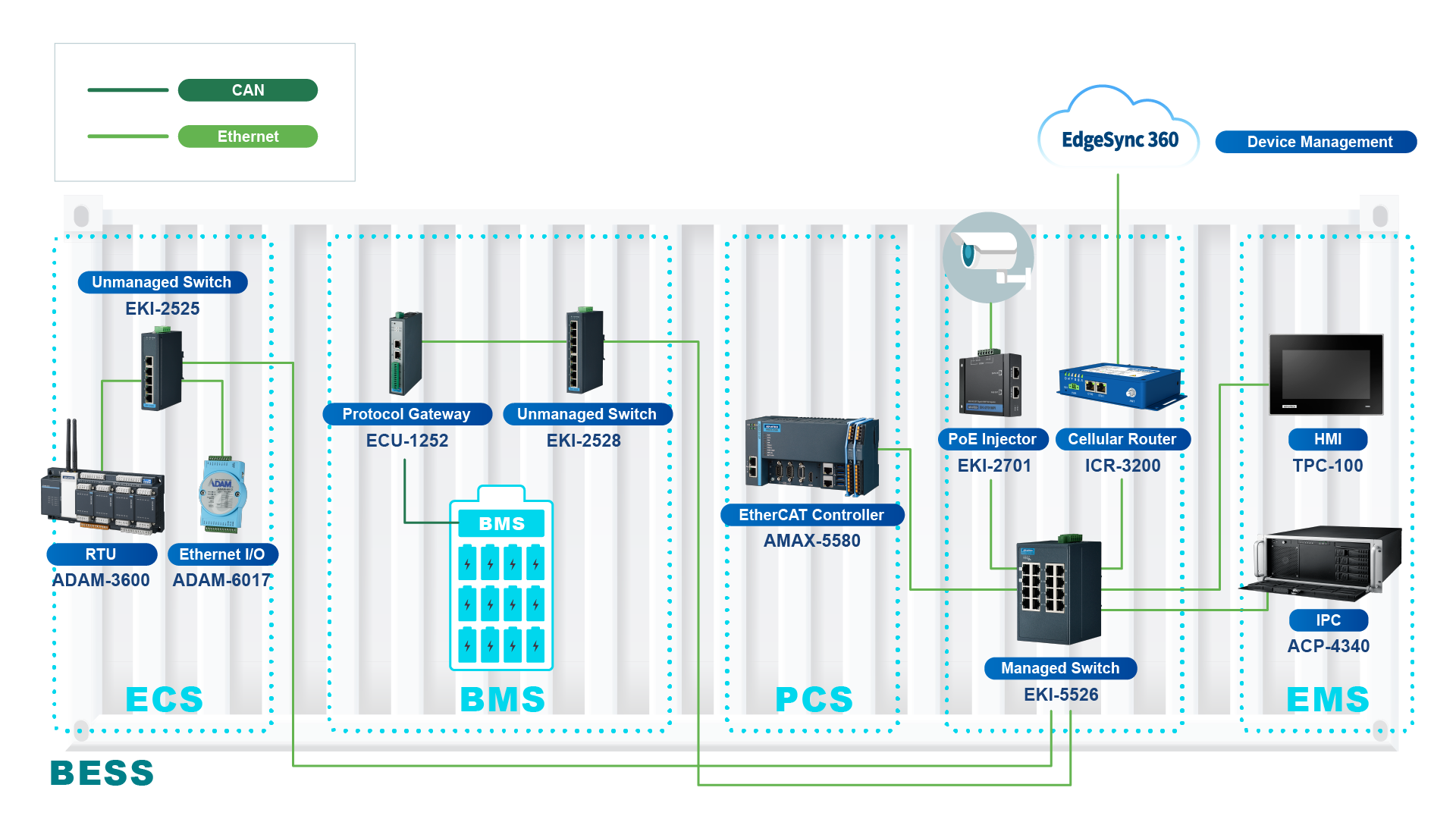

BESS systems with a capacity of less than 1 MW are typically designed to fit within a single container, which includes many batteries, a battery management system, a power conversion system (PCS), and an energy management system (EMS). These all-in-one BESS systems can be scaled from utility scale to industrial and commercial applications.

The environmental control system (ECS) within the container combines the fire and HVAC systems to maintain a stable environment. ECS detects abnormal temperature changes of the HVAC system through various I/O nodes connected to ADAM-6017 and ADAM-3600. This is critical for the long-term operation of BESS.

The battery management system (BMS) is responsible for real-time monitoring and load control of each battery cell. A BMS typically uses CANBus for external communication, and a communication gateway, such as ECU-1252, is required to convert CanBus data to Ethernet data. The ECU-1252 gateway with EdgeLink supports CANBus interfaces and multiple power protocols, including IEC-61850 MMS, DNP3, and IEC-60870-5-104, ensuring seamless data transmission and power dispatch to utility grids.

The PCS is the core of electricity scheduling and dispatch, as it converts AC and DC power with the focus on real-time control using the AMAX-5580 EtherCAT controller. The EMS typically includes SCADA software and industrial computers (IPCs) working together to provide overall monitoring of the energy storage container. Usually, two sets of IPCs provide backups of each other for SCADA stability, while the other two sets provide backups of each other for database redundancy.

Moreover, Advantech’s industrial routers support WebAccess/VPN, providing a secure cellular environment from BESS to larger communication networks.

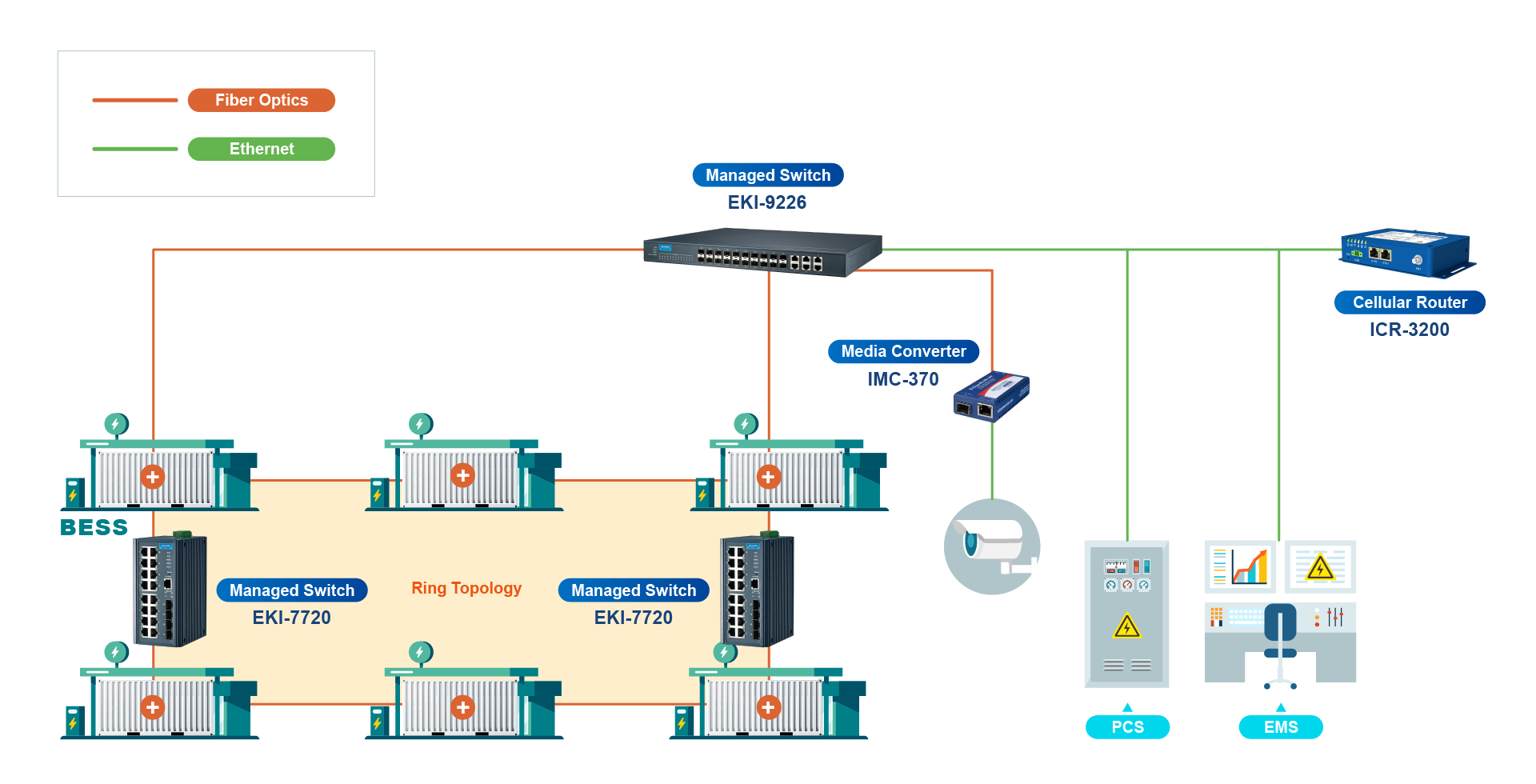

In a large grid-scale energy storage field, BMS, PCS, and EMS operate in different containers, and each container must maintain data communication at all times to manage charging and discharging in the large-scale power grids.

Each container is connected using fiber optic ring topology to enhance network redundancy and ensure the highest stability. By leveraging switches managed by the Advantech EKI-7700, each BMS is connected and converts Ethernet signals into fiber optic signals. This way, we can ensure seamless data exchange between distributed BMS containers.

On the top layer of the ring network, we use IEC 61850-3 certified managed EKI-9200 series switches to connect PCS, EMS, and multiple BMS containers. Since security management of the energy storage system is critical, we also employ the IMC-370 series media converter to extend the 10/100/1000Mbps twisted-pair network over fiber technology to connect with surveillance cameras, and transfer the video signals back to the network for security monitoring.

All of the BESS containers can manage charging and discharging via the IEC 61850 protocol to connect with national power grids through communication using ICR-3200 series 4G/LTE routers, and achieve peak shaving, frequency regulation, and energy management.

Battery energy storage systems (BESS) are designed for different purposes. The BESS that are

commonly installed in commercial buildings and homes are known as behind-the-meter

BESS. They offer several benefits, such as reducing energy costs through demand management,

providing back-up power, and offering the capacity to handle peaks.

One key advantage is the ability to perform peak shaving, which helps flatten demand peaks

and avoid peak demand charges. Moreover, these small-sized battery storage systems ensure

power availability during peak hours.

In a compact behind-the-meter BESS setup, the ADAM-6217 Ethernet I/O is utilized to collect

HVAC data, including temperature changes. This data is then connected to the ECU-1252

gateway which employs a CANbus interface to convert battery management system (BMS) data

to Ethernet networks. The WOP-200K series visualization gateway serves as a human-machine

interface, facilitating efficient visualization of BESS data.

To establish connectivity, all the machines are linked to the EKI-2528 8-port unmanaged switch,

which subsequently transmits the acquired data to an energy management system (EMS).

Additionally, the EdgeSync 360 edge device management cloud service enables remote monitoring

and management of devices across all behind-the-meter BESS installations, ensuring overall

microgrid stability.